LANSMONT

Lansmont equips product and packaging engineers with cutting-edge testing technology to uncover the challenges of the products that may face in transport and use. The solutions help engineers enhance product strength and durability, optimise protective packaging solutions, and ultimately drive business success through improved product quality.

Field Monitoring Instruments

SAVER™ AM – Asset Monitor

The SAVER™ AM is a high-performance data logger, providing an autonomous, rechargeable platform for monitoring the movement of critical assets throughout the supply chain.

- Self-powered filed data logger with an internal tri-axial accelerometer.

- Provided with temperature, humidity, and atmospheric pressure sensors, as well as both light and orientation sensor.

- Powered by a USB-rechargeable lithium-ion battery, providing up to 30 days of continuous operation.

SAVER™ 3X90

The award-winning SAVER™ 3X90 is a “best in class” field data recorder. This self-powered instrument provides 16-bit resolution, internal triaxial accelerometer and temperature and humidity sensors.

- The award-winning SAVER™ 3X90 is a “best in class” field data recorder.

- Self-powered filed data logger with an internal tri-axial accelerometer.

- Provided with temperature and humidity sensor.

- Powered by 9V lithium batteries, the instruments will operate continuously for up to 90 days.

- 16-bit resolution electronics allow you to take precise measurements of your dynamic environment.

SAVER 9XGPS

Built-in GPS capabilities allow for position and speed data to automatically be directly embedded into captured data files.

- Enhanced version of SAVER™ 9X30.

- Includes built-in signal conditioning and can record up to 9 dynamic channels-an internal triaxial accelerometer as well as 6 external accelerometer inputs.

- Powered by 9V lithium batteries, the instruments will operate continuously for up to 30 days.

- Provided with temperature, humidity and atmospheric pressure sensors.

Color 3D Scanner

iReal 2E Body scanner maximizes the performance in depth of field, scanning area, algorithm, texture reproduction, and detail capturing, specially designed for medium to large-sized objects and human body 3D scanning.

- HD colour reproduction

- Alignment accuracy up to 0.300 mm/m

- Support 3D printing

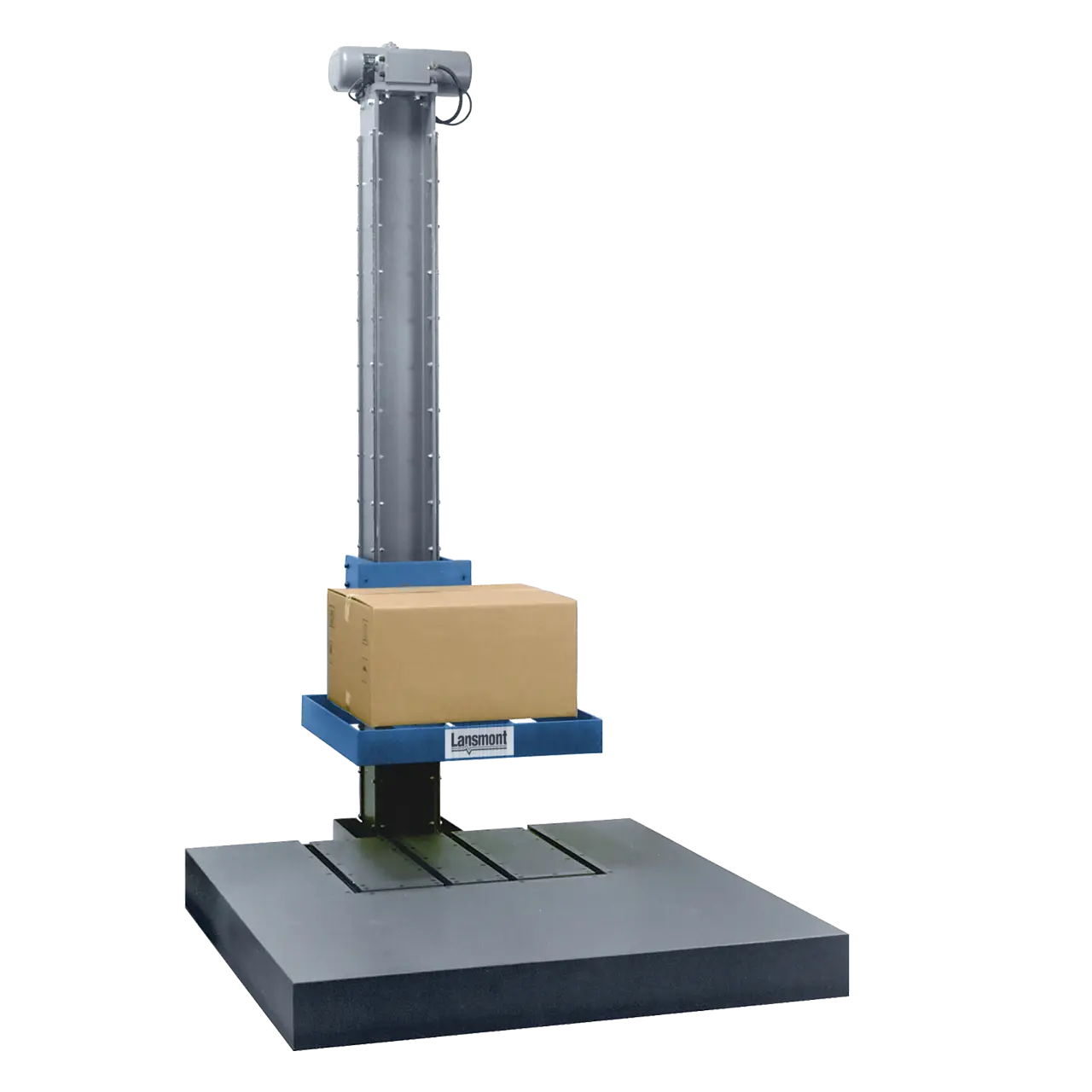

Drop Test System (PDT 300)

Built-in GPS capabilities allow for position and speed data to automatically be directly embedded into captured data files.

- Enhanced version of SAVER™ 9X30.

- Includes built-in signal conditioning and can record up to 9 dynamic channels-an internal triaxial accelerometer as well as 6 external accelerometer inputs.

- Powered by 9V lithium batteries, the instruments will operate continuously for up to 30 days.

- Provided with temperature, humidity and atmospheric pressure sensors.

Shock Test System (P95/115)

Lansmont’s P95/115 Shock Test System can be equipped with optional shock pulse programmers to generate a wide range of half sine pulses & more.

- Designed for shock tests on electronic specimens such as PCB boards, electrical end products, automotive parts, packaging etc.

- Accurately measures the fragility of products and evaluates how they respond to specific shock inputs/pulse.

- Shock test data is key information when determining if a product can withstand its intended distribution and use environment.

- The included Damage Boundary Programmers perform short duration half sine and long duration trapezoidal shock pulses which are commonly used for a wide range of shock fragility tests.

- The ideal solution for testing larger products where pulse quality and system reliability are of critical importance.

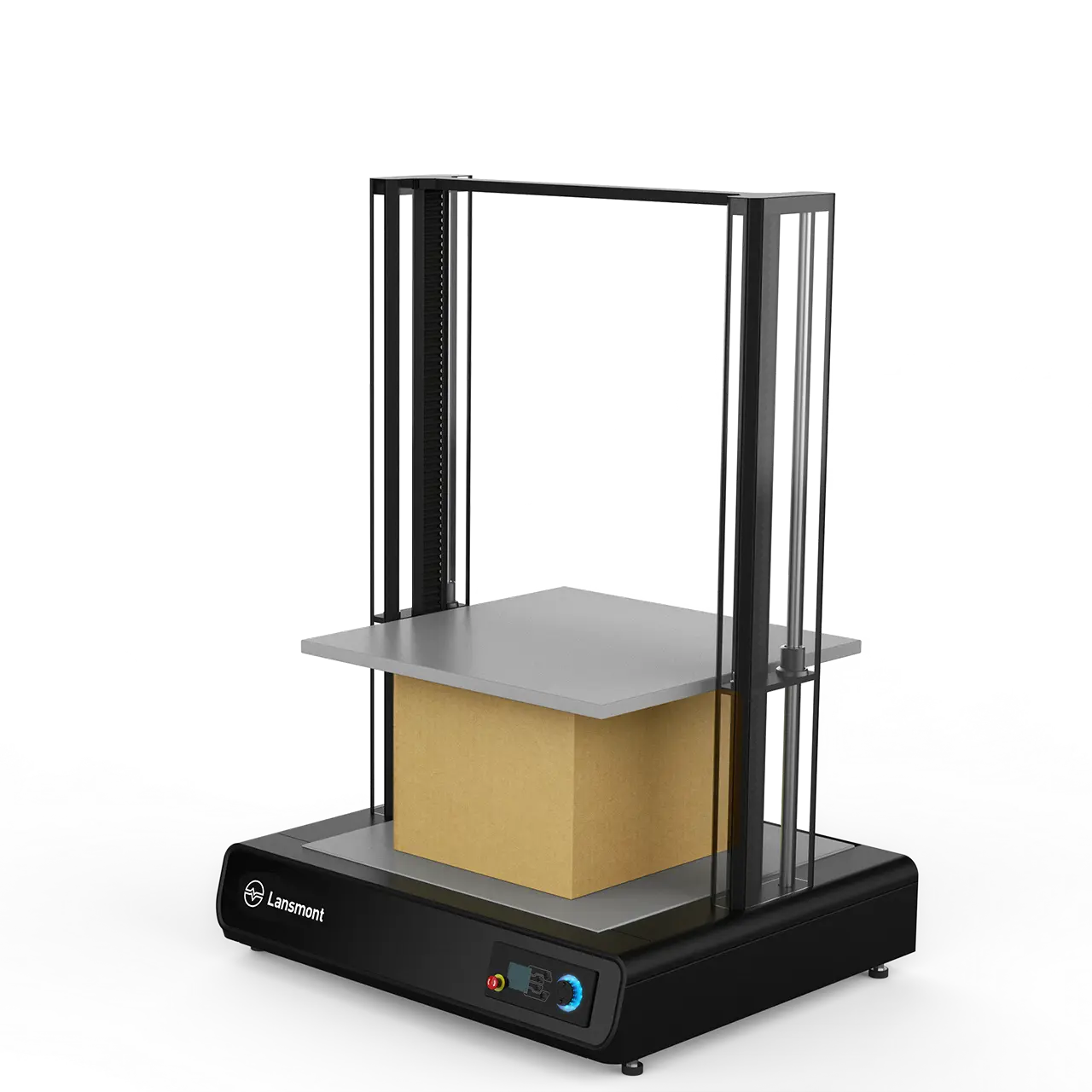

Compression Test System (SqueezerPro)

The SqueezerPro is a valuable tool for researching the effects of various board mediums, closures, interior partitions and other box design variables on compressive strength performance.

- Designed to simulate the stacking force generated during warehouse storage and transit.

- Compression tests play a crucial role in the package design process, as they determine the performance of unit loads, individual packages, components and materials under compressive loads.

- The data collected using this system enables engineers to minimise damage, costs and liability associated with stacking failures.

- Valuable tool for researching the effect of various board mediums, closures, interior partitions and other box design variables on compressive strength performance.

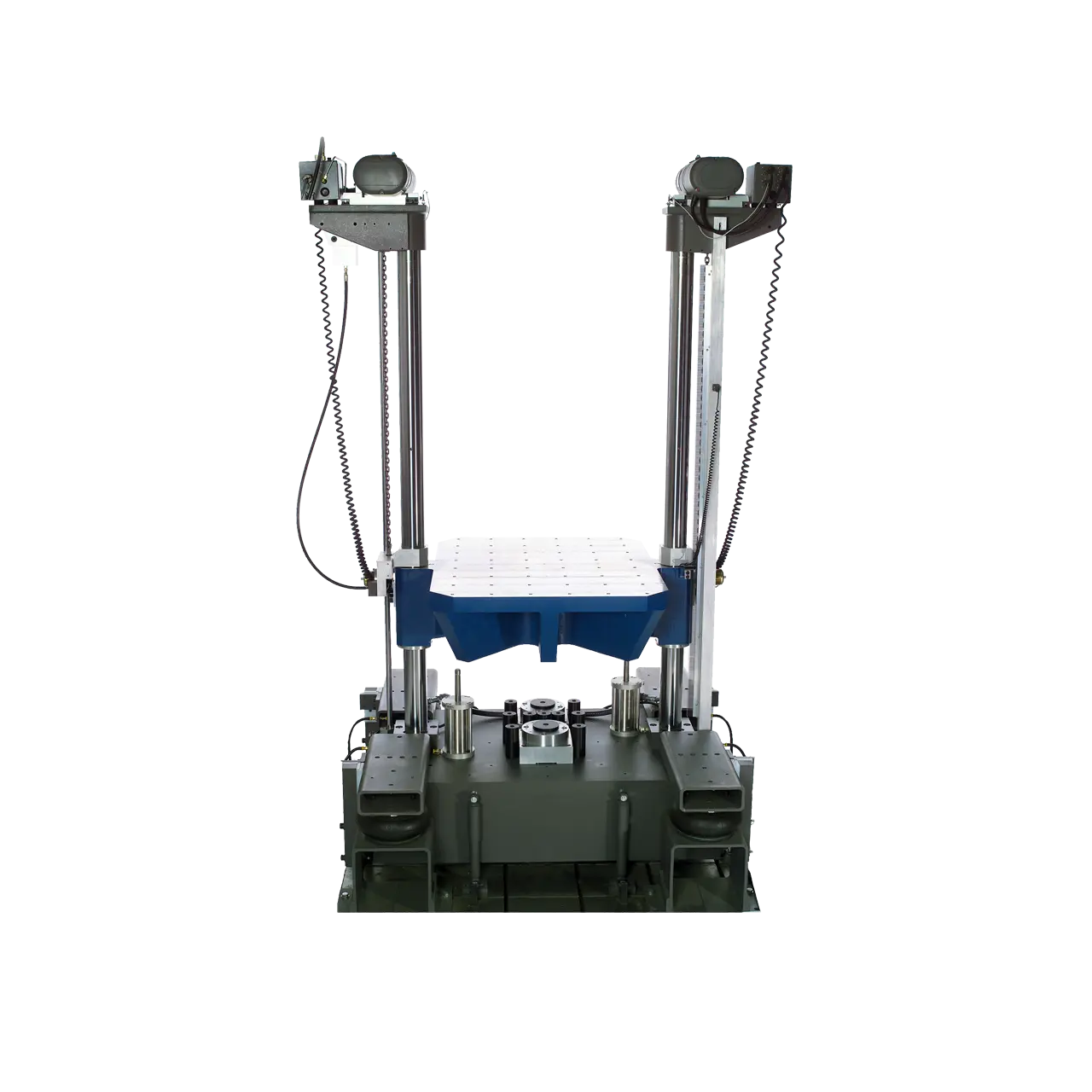

Hydraulic Vibration Test System (1800)

Lansmont’s Model 1800 is one of the most popular models in vibration test systems. This is a good fit for many product and package testing applications.

- Used to evaluate resonant frequencies of product and package designs as well as to simulate the random vibration that occurs in the distribution or in-use environment during transportation.

- Specifically designed to meet a wide range of ASTM, ISO, JIS, DOT, MIL, ISTA, and federal standards for vibration testing.

- The complete system features a rugged hydraulic actuator, a reliable hydraulic power supply and Lansmont’s TouchTest Vibration Controller.

- The system can perform random vibration, Field-to-Lab® simulations, resonance search and dwell, sine sweep and repetitive bounce tests all under closed loop computerised control.

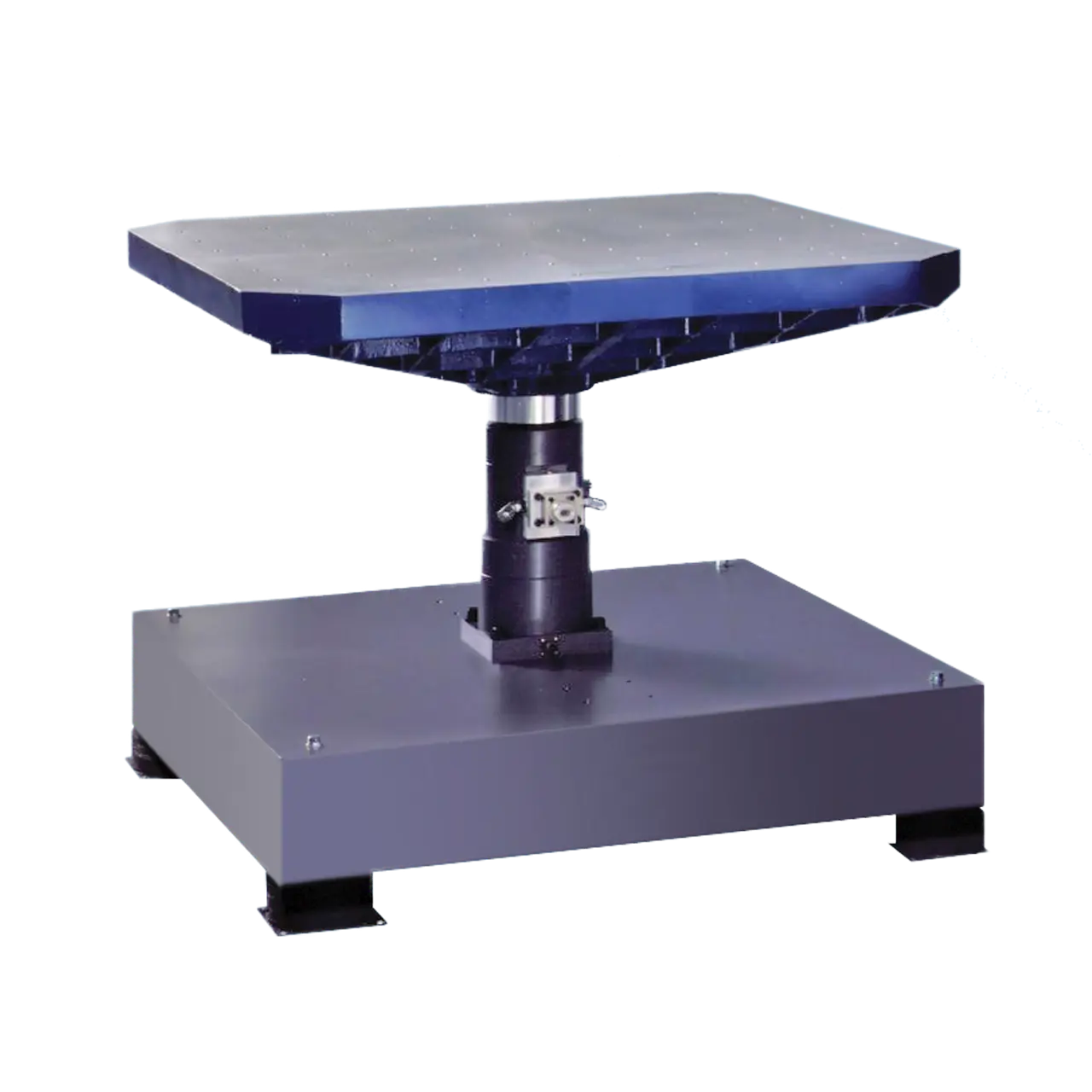

Mechanical Shaker (MS400)

The MS 400 performs repetitive shock, loose load, or bounce tests, it can handle individual packages or containers weighing up to 181 kgs.

- Mechanical Shaker provides entry level vibration testing to evaluate repetitive shock.

- Used for testing packed products to determine their ability to withstand vibration and dynamic impact energy during transportation.

- Low-cost testing equipment option for challenging the integrity of your packing designs.

- Testing electronic products and components for loose solder connections and hardware failure.

- Performs repetitive shock, loose load, or bounce tests, it can handle individual packages or containers weighing up to 181kg.

- The operating frequency range is from 2 – 5 Hz, with a fixed 2.54 cm displacement and a maximum acceleration of 1.25g peak.

Inclined Impact Test System

(IT 152-4K)

The IT 152-4K performs inclined impact tests simulate distribution handling hazards. Our design meets traditional industry specifications with the added benefits of some innovative design ideas.

- Used for railway transportation testing purposes.

- Inclined impact testing simulates environmental dynamic forces that packaged goods may endure throughout transport and handling operations.

- These hazardous dynamics are simulated using an impact test system.

- Inclined impact test system utilises a carriage that propels the test sample down a ramp at predetermined velocities before impacting into a fixed backstop.

- The slope impact test machine is applied to evaluate the pile-up of goods, electromechanical sliding, engine loading and product transportation.

- Its purpose is to determine whether various properties fail under normal and extreme collision conditions when a product is subjected to a series of shocks.